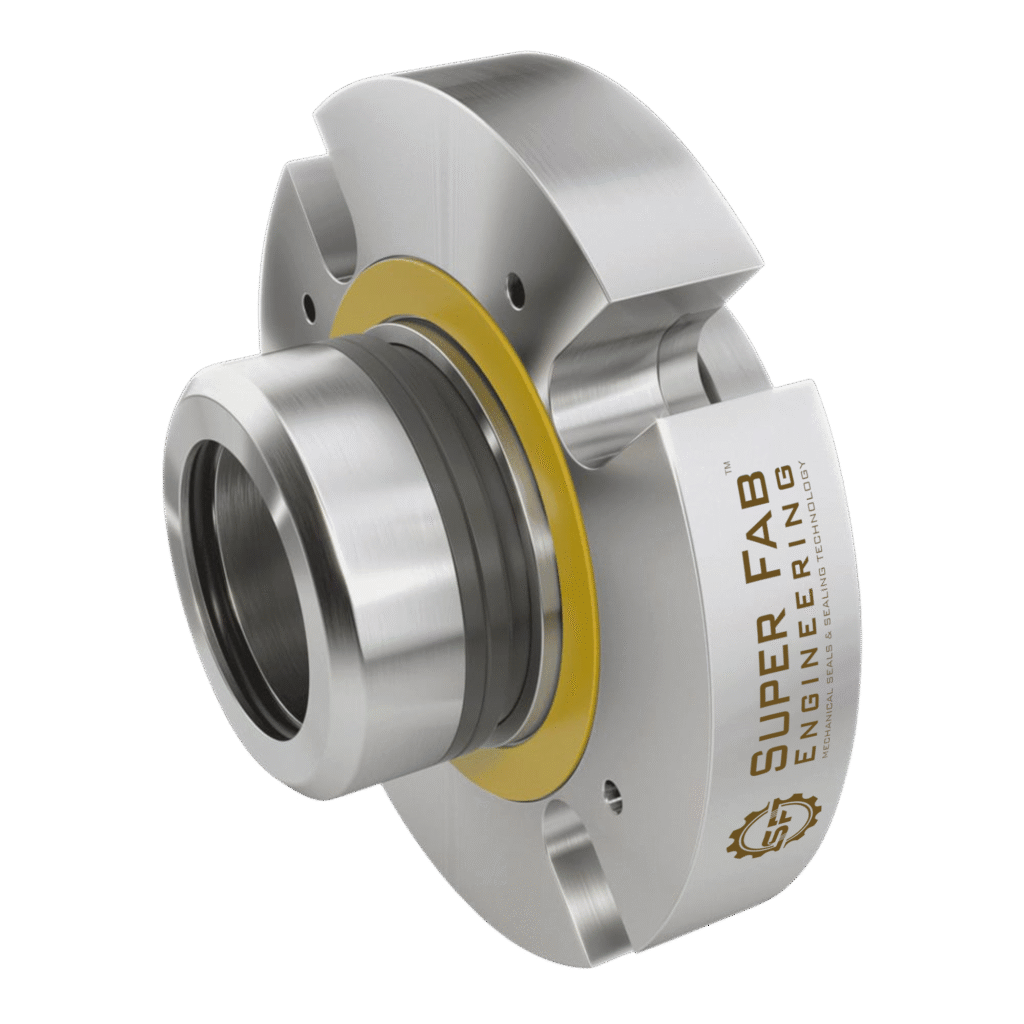

High Pressure Cartridge Seal

Material

Seal Face:

Secondary Seals:

Metal Parts:

Carbon, Silicon, Ceramic, TC

Viton / PTFE / GFT / FFKM

SS 316, Alloy 20,

Operating Limits

Pressure:

Temperature:

Speed:

Sizes:

15 bars (Max), Upon Special Application & Customer Requirements We can able to provide Upto 80 - 100 bar

(-)80°C to (+)180°C

Up to 2500 to 8000 rpm (max)

25 mm to 150 mm

Product Description

High-Pressure Mechanical Seals are expertly engineered for heavy-duty, high-torque applications that demand exceptional sealing performance. Built with a robust structure and a positive drive system, these seals are specifically developed to withstand the rigors of high-pressure operations, offering long-term durability and dependable functionality. The incorporation of multiple springs ensures even load distribution across the seal faces, enhancing sealing efficiency and wear resistance.

Supplied as a pre-assembled cartridge unit, these seals are designed for direct mounting onto the stuffing box, allowing for quick and easy installation while protecting delicate sealing surfaces from damage during setup.

Ideal for medium to high-pressure environments, High-Pressure Cartridge Seals provide a streamlined, factory-built solution that simplifies installation and minimizes the risk of alignment issues. This smart, user-friendly design makes them a top choice for demanding industrial processes where performance and reliability under pressure are critical.

Applications

Heavy-duty high-pressure pumping systems

Fertilizer manufacturing units

Nuclear energy facilities

Oil refining and processing plants

Features

Offered in both pressure-balanced and unbalanced variants

Single-face sealing configuration

Compatible with internal or external installation

Equipped with a multi-spring arrangement

Reinforced with a robust torque transmission system

Operates reliably in either rotational direction